-40%

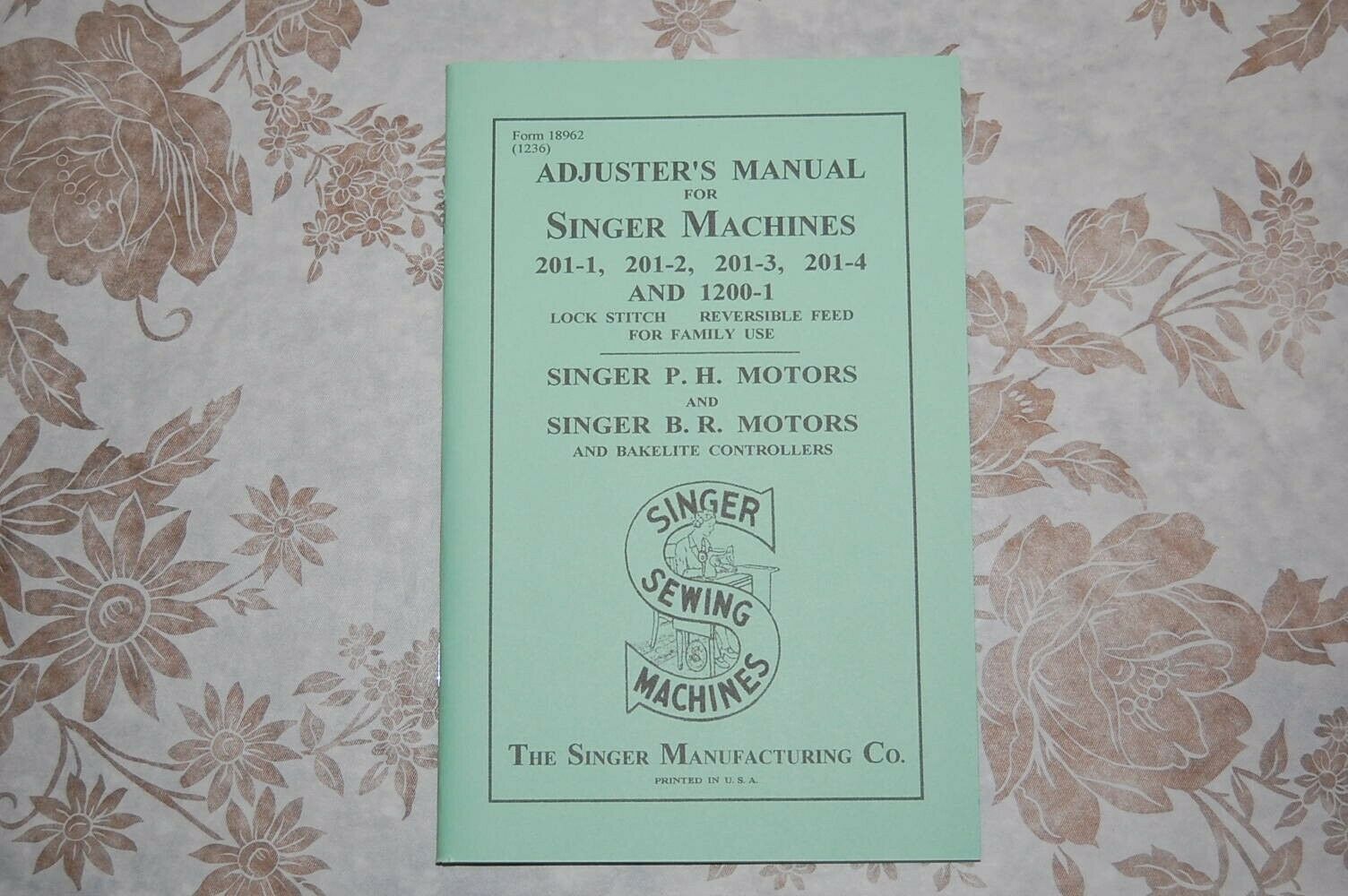

Adjusters Manual for Timing, Adjusting & Service Singer 201 1200 Sewing Machines

$ 10.5

- Description

- Size Guide

Description

Adjusters Manualfor

SINGER SEWING MACHINES

201-1, 201-2, 201-3, 201-4 and 1200-1

*********

Timing and Adjusting Instructions

for

Servicing, Adjusting and Repairing

Singer Sewing Machines

of Classes

201 and 1200

*********

Instruction Manual. (Photo 03)

This is NOT a standard "Xerox"

copy of the Singer manual!

This manual is professionally printed

on the same heavy-weight brilliant-white chrome paper as the

original Singer manual!

Brilliant-white heavy-weight chrome paper

. (photo 04)

Description:

This listing is for a professional reproduction of the Singer Manufacturing Co. “Adjuster's Manual for Singer Machines 201-1, 201-2, 201-3, 201-4 and 1200-1 Lock Stitch Reversible Feed Sewing Machines.”

The manual also includes instructions for the Singer P.H. and B.R. Sewing Machine motors as well as for the Singer Bakelite speed controller pedal.

This is NOT a standard "Xerox" copy of the Singer manual! It is professionally printed on the same brilliant-white heavy-weight paper as the original Singer manual! It is super clean, the text and the illustrations are very sharp, and it is nearly identical in size and in paper type to the original Singer manual.

Unlike the original 80 year old manual that has become frail, brittle, mildewed, stained and yellowed after so many years, this manual looks like an original Singer manual that has been preserved in NEW CONDITION!

Just like the Singer company printed their manual on their in-house printing press, we printed this manual on our in-house printing press. This manual may also serve you for the next 80 years.

In fact, if we didn't tell you,

you could not tell the difference

between this manual and the

original manual!

This full-size 68-page Instruction manual is complete and very clean with no "black dots," smudges, stains, or any other imperfections. No pages are missing, dirty, or damaged. The manual includes descriptions and illustrations which will show you how to do the following:

·

Description

·

Motors for machines 201-2 and 201-3

·

Singer P.H. Motors for machine 201-2

·

Singer B.R. Motors for machine 201-3

·

Insure correct demonstration of the machine

·

Electrical connections for machines 201-2 and 201-3

·

Machine 201-2, Singer P.H. motor, Singer-light and controller

·

Singer-light leads

·

Controller leads

·

Machine 201-3, Singer B.R. motor, Singer-light and controller

·

Singer-light leads

·

Controller leads

·

Using the Bakelite controller

·

Using the foot control

·

Using the knee control

·

Causes of trouble with machines of class 201

·

Causes of low speed or failure to run

·

Heavy or gummed lubricant

·

Too much presser foot pressure

·

Machine Binds

·

Motor causes of trouble with machines 201-2 and 201-3

·

Electric current not turned on

·

Loose or broken electrical connections

·

Motor not suited for electric supply

·

Dirty commutator

·

Carbon brushes not making contact

·

Armature binding

·

Machine 201-2

·

Machine 201-3

·

Causes of binding machine 201-2 and 201-3

·

Machine 201-2 only

·

Machine 201-3 only

·

Broken armature wires

·

Controller not properly adjusted

·

Inspect electrical connections, machine 201-2

·

Three-pin terminal

·

Motor, machine 201-2

·

Singer-light, machine 201-2

·

Remove Singer-light shade, machine 201-2

·

Inspect Singer-light connections, machine 201-2

·

Reassemble the Singer-light, machine 201-2

·

Replace Singer-light, machine 201-2

·

Remove Singer-light leads from the machine arm, machine 201-2

·

Replace the Singer-light leads, machine 201-2

·

Replacthe three-pin terminal, machine 201-2

·

Instructions for machines 201-2 and 201-3

·

Tree-pin terminal plug

·

Singer-light fails to light, machines 201-2 and 201-3

·

Remove and replace the bulb, machines 201-2 and 201-3

·

Remove the motor, machine 201-2

·

Disassemblethe

motor, machine 201-2

·

Remove motor cover

·

Remove brushes, machine 201-2

·

Remove armature, machine 201-2

·

Inspect and clean the armature, machine 201-2

·

Remove the field core with coils, machine 201-2

·

Clean brushes and brush tubes, machine 201-2

·

Inspect wire connections to brush tubes, machine 201-2

·

Remove and replace brush tubes, machine 201-2

·

Remove and replace insulating bushings, machine 201-2

·

Reassemble the motor, machine 201-2

·

Reassemble the field core with coils

·

Replace armature, machine 201-2

·

Replace brushes, machine 201-2

·

Attach motor and three-pin terminal, machine 201-2

·

Lubricating the Motor,

machine 201-2

·

Remove and replace the balance wheel

,machine 201-2

·

Remove and replace the Textolite gear and shock-absorbing spring

,machine 201-2

·

Inspect electrical connections, machine 201-3

·

Tree-pinterminal, machine 201-3

·

Motor, machine 201-3

·

Singer-light, machine 201-3

·

Singer-light fails to light, machine 201-3

·

Remove and replace the bulb, machine 201-3

·

Tree-pin terminal, machine 201-3

·

Electrical outlet plug, machine 201-3

·

Remove the motor, machine 201-3

·

Disassemble the motor, machine 201-3

·

Remov the pulley, machine 201-3

·

Remove pulley end cover, machine 201-3

·

Remove the brushes, machine 201-3

·

Remove the armature, machine 201-3

·

Inspect and clean the armature, machine 201-3

·

Remove the field core shield, machine 201-3

·

Inspect wire connections to brush tubes, machine 201-3

·

Clean brushes and brush tubes, machine 201-3

·

Reassemble the motor, machine 201-3

·

Replace commutator end cover, machine 201-3

·

Replace field core shield, machine 201-3

·

Replace armature, machine 201-3

·

Replace pulley end cover, machine 201-3

·

Replace brushes, machine 201-3

·

Replace pulley, machine 201-3

·

Attach motor, Singer-light and three-pin terminal, machine 201-3

·

Adjust belt tension, machine 201-3

·

Lubricate the motor, machine 201-3

·

Singer Bakelite carbon controller, machines 201-2 and 201-3

·

The

S

inger Bakelite controller

·

Motor fails to start

·

Inspect the carbon resistance unit of the controller

·

Treadle controller

·

Convertible foot and knee controller

·

Motor fails to operate at all speeds

·

Emergency adjustment of carbon resistance unit

·

Motor fails to stop

·

Instructions for machines 201-1, 201-2, 201-3, 201-4 and 1200-1

·

Remove and replace the rotating hook bobbin case

·

Remove and replace the feed dog

·

Remove and replace the rotating hook bobbin case position plate

·

Remove and replace the rotating hook

·

Time the rotating hook

·

Set the needle bar at the correct height

·

Remove and replace the rotating hook shaft and bevel gear

·

Remove and replace the rotating hook driving shaft and bevel gears

·

Raise or lower the feed dog

·

Adjust the position of the feed dog lengthwise

·

Adjust the position of the feed dog centrally

·

Remove and disassemble the graduated tension

·

Reassemble and replace the graduated tension

·

Adjust the bobbin winder

·

Adjust the presser bar

·

Remove and replace the presser bar

·

Remove and replace the needle bar

·

Remove and replace the feed connecting rod

·

Remove and replace the feed forked connection and feed regulator

·

Remove and replace the upright arm shaft and gears

·

Remove and replace the horizontal arm shaft, bushing, gear, cam, eccentric

·

O

iling the machine

Here are photos of some of the pages from the manual. You can see the

superb quality of the print, photos, diagrams, and the paper itself.

P.H. motor, Singer-light and controller

. (Photo 04)

Light fixture assembly. (Photo 07)

Three-pin terminal

. (Photo 08)

Motor assembly. (Photo 10)

Electrical connections

. (Photo 12)

Speed controller

. (Photo 15)

Timing the rotating hook

. (Photo 17)

These instructions are fairly detailed and utilize illustrations to make it easy to understand and carry out the instructions. In most cases a simple tool, like a screwdriver, is needed to do the task. And, once you know what to do, you may be able to perform the timing or the adjustment in just a couple of minutes!

These Instructions are a

MUST

for every owner

of a Singer

201-1, 201-2, 201-3, 201-4, 1200-1

Sewing Machine!

Instruction Manual. (Photo 01)

Note for users of “Singer Adjusters Manual for Class 201”

:

Most people who use this manual also use an additional manual which includes service information that is directly applicable to Class 201 machines.

This additional manual is:

“

Illustrated List of Parts for Class 201

”

(available at our eBay listing #

265095307071

)

The additional “Illustrated List of Parts Manual” includes illustrations of every single component, screw, nut, spring, plate,rod, hinge, handle, arm, etc. Every internal part of the motor is shown. Every internal part of the speed control pedal is shown. All the components and parts of every single accessory are shown. All these parts and components are illustrated in the proper size with respect to their actual size and with respect to each other.

This“

Illustrated List of Parts for Class 201

” manual is available at our eBay listing #

265095307071

.